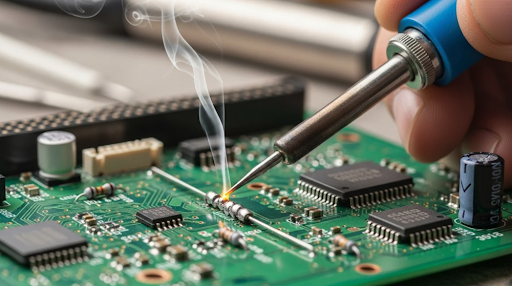

Ensuring the air quality in any industrial setting is crucial for employee health and operational efficiency. For facilities involved in soldering, a high-performing solder fume extractor is not just an option; it’s a necessity. These systems are vital for capturing harmful particulates and gases at the source. However, simply installing this equipment is not enough. To guarantee its effectiveness and longevity, a consistent and professional maintenance schedule is essential for protecting your investment and your team.

The Importance of Regular Upkeep

A fume extraction system is a complex piece of machinery with multiple components working together. Over time, filters clog, motors wear out, and ductwork can accumulate residue. Neglecting these issues can lead to a significant drop in performance, higher energy consumption, and eventual system failure.

Maximizing Filtration Efficiency

The core function of a fume extractor is to filter contaminants from the air. This is achieved through a series of filters that capture particles of various sizes.

As these filters capture solder fumes and dust, they gradually become saturated. A clogged filter restricts airflow, which reduces the system’s ability to capture fumes at the source. This not only compromises air quality but also puts extra strain on the extractor’s motor, forcing it to work harder. Regular, professional filter inspection and replacement are critical to maintaining optimal suction and filtration, ensuring a safe breathing environment.

Protecting Your Investment

Scheduled maintenance is a proactive approach to asset management. It allows technicians to identify and address minor issues before they escalate into major, costly repairs.

Catching problems like a worn motor bearing or a small leak in the ductwork early can prevent a complete system breakdown. This proactive care extends the operational lifespan of the equipment significantly, ensuring you get the maximum return on your investment. It also helps in understanding if you need a solder fume extractor that is better suited to your specific operational demands as your business evolves. A well-maintained unit will reliably serve your facility for years to come.

Ensuring Consistent Operational Safety

The primary goal of a fume extraction system is to protect employees from inhaling hazardous substances. A poorly maintained unit cannot perform this function effectively.

When an extractor’s performance declines, it fails to capture fumes efficiently, allowing them to escape into the workplace. This creates a direct health risk for personnel. A structured maintenance plan guarantees that the system operates according to safety standards, providing consistent and reliable protection. This commitment to safety not only protects your team but also helps maintain regulatory compliance.

Conclusion

Implementing a scheduled maintenance program for your solder fume extraction equipment is a fundamental practice for any responsible operation. It directly impacts system performance, extends the equipment’s lifespan, and upholds a safe working environment. By partnering with professionals for regular upkeep, you ensure your system runs efficiently, prevent expensive emergency repairs, and provide continuous protection for your employees. This proactive strategy is key to maintaining both operational integrity and a healthy workplace.